The term "sustainability" has become increasingly popular in recent years. It is frequently seen in

headlines, featured in forms of news media, scientific research, and practical seminars. Is the word

sustainability merely a trending word or the question of the hour?

The emphasis on sustainability stems from global growing awareness intended for critical environmental

issues and climate change, largely caused by human activity. The focus on sustainability reflects our deep

commitment to the principles of securing a better future for the planet and generations to come.

Consequently, sustainability has gained prominence in various fields, ranging from everyday life and

business to transportation, urban planning, and manufacturing. Manufacturing should unquestionably be

sustainable. Today, there is widespread recognition and agreement regarding the correctness of this

statement. Manufacturing processes use natural resources, consume energy, create waste, and pollute the

environment. We can mitigate the negative environmental impact only by adopting sustainable production

technologies.

Machining remains a primary method for producing parts of machines and mechanisms. Therefore, the question

of how to make machining sustainable is relevant more than ever. A cutting tool contacts the machined

workpiece directly and shapes it to its required form, removing the rest of the unnecessary material in the

form of metal chips. Can a cutting tool be a key factor for improving sustainability? The answer to the

above question is undoubtedly a resounding, yes!

Despite its smaller size in comparison to other elements of a technological system, the machine or

workholding fixture called the cutting tool can play a pivotal role in achieving sustainable manufacturing

practices. The cutting action involved in material removal during machining is an energy-intensive process.

However, the cutting tool is designed to be energy-efficient and, therefore, can significantly reduce energy

consumption.

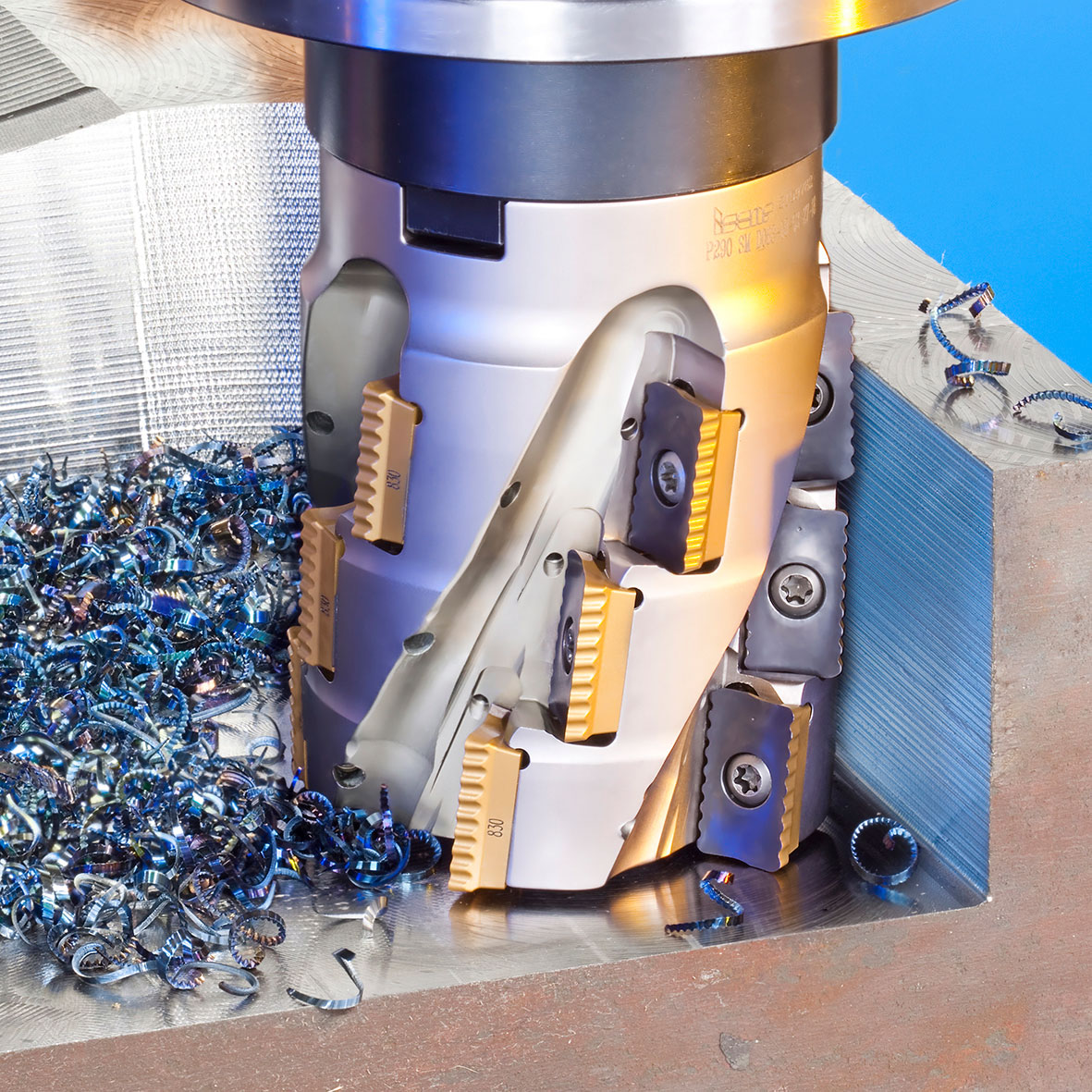

The impact of key tool characteristics cannot be underestimated. Advanced cutting geometries minimize

cutting forces while anti-vibration designs mitigate chatter, which causes force oscillation. Progressive

coatings enhance lubricity, diminishing friction, and efficient cooling methods effectively reduce heat

generation. Collectively, these tool elements substantially reduce the environmental impact of machining

operations.

In many instances, a cutting tool can hinder productivity growth, limiting the full realization and

capabilities of modern machines. Therefore, tools that guarantee higher productivity play a crucial role in

reducing cutting time, machine power consumption, and greenhouse gas (GHG) emissions. Reliable, long-lasting

cutting tools that enhance tool life, reduce the frequency of tool replacements, or insert indexing. This

diminishes machine downtime associated with tool changes, ultimately improving overall manufacturing

efficiency.

In addition, utilizing cutting tools that provide a better surface finish can eliminate the need for finish

machining operations, thereby decreasing the machining allowance or material stock to be removed. As a

result, a dual effect is achieved reducing both machining time and material waste.

Hence, the term "sustainable cutting tool" is not merely a passing trend but a vital concept that is

progressively embraced and integrated as a fundamental principle of sustainable manufacturing. Ultimately

the main parameter to analyze a tool is its performance. However, the component of tool sustainability has

become a contemporary factor of paramount importance. Understanding the various aspects of how cutting tools

impact sustainability largely shapes the requirements for modern tools and guides their development.

A case study featuring how ISCAR's tools improve machining sustainability.

How can a cutting tool improve machining sustainability? A brief review of select ISCAR products helps us to

understand this profoundly. The design concept of tools with replaceable cutting parts significantly

contributes to the sustainable utilization of cutting material.

ISCAR's tool systems with exchangeable carbide heads, such as MULTI-MASTER and SUMOCHAM, provide a good

example of this concept by allowing the rational use of cemented carbides. In addition to the traditional

approach of saving cutting material, the mentioned systems offer further advantages related to

sustainability. Both the MULTI-MASTER and SUMOCHAM families feature high repeatability, which allows for the

realization of the NO-SETUP-TIME principle. This means that replacing a worn head does not require

additional setup operations to adjust tool parameters. As a result, machine downtime is significantly

reduced.

LOGIQ-3-CHAM represents the next step in the development of drilling tools with exchangeable heads, based on

the features of its predecessor, the SUMOCHAM drilling line. One notable parameter that sets LOGIQ-3-CHAM

apart from the other drilling systems is its three flutes (Fig. 1), as opposed to the traditional two. This

change enables increased feed and speed of up to 50%. Alongside improved productivity, this new design also

brings sustainability advantages by reducing energy consumption and GHG emissions. Drilling 16mm diameter

holes with an 80mm depth in a part made from low alloy steel exemplifies these features well. With a tool

life of 500 holes, when compared to a competitor's drill with a replaceable two-flute head, the use of

ISCAR's LOGIQ-3-CHAM tool results in a 26% decrease in cycle time and a 19% decrease in energy consumption.

Consequently, CO2 emission is reduced by 19%.

The anti-vibration design of cutting tools plays an essential role in reducing power consumption, extending

tool life, and improving the surface finish of the generated surface. ISCAR has developed vibration-damping

solutions that use various principles. These include vibration damping through specially designed

mechanisms, such as in boring bars (Fig. 2), as well as the development of specific chatter-resistant

cutting geometries. The geometry incorporates variable helix and unequal angular pitch in multi-flute solid

carbide endmills and heads, along with a serrated cutting edge for effective chip splitting action in

indexable inserts (Fig. 3). Additionally, these tools and inserts ensure better chip handling, which

enhances the performance of machining operations. The smart design of the pocket reducer allows mounting

smaller size inserts, which provides the option of extending the use of existing tool bodies instead of

purchasing new ones. This not only reduces the waste of raw materials but also helps decrease GHG emissions.

Additive manufacturing (AM) has introduced new sustainability features in tool design. Firstly, AM

technologies enable the production of a tool body that closely resembles its final shape, minimizing the

need for finish machining and significantly reducing tool material consumption. Additionally, these

technologies make it easier to create inner coolant channels in an optimal manner, improving the coolant

flow through the tool body to the cutting zone.

The examples featured in this article illustrate how energy- and material-efficient, durable cutting tools

can have a significant impact on technological sustainability. Such tools not only help reduce energy

consumption and waste, but also contribute to cost savings and environmental stewardship.