Page 3 - Threading_Handbook

P. 3

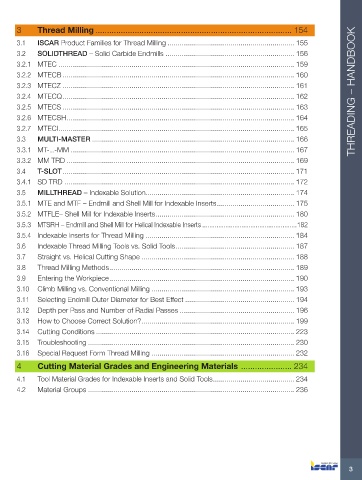

3 Thread Milling ..................................................................................... 154

3.1 ISCAR Product Families for Thread Milling ................................................................ 155

3.2 SOLIDTHREAD – Solid Carbide Endmills ................................................................. 156

3.2.1 MTEC ....................................................................................................................... 159

3.2.2 MTECB ..................................................................................................................... 160

3.2.3 MTECZ ..................................................................................................................... 161

3.2.4 MTECQ ..................................................................................................................... 162 THREADING – HANDBOOK

3.2.5 MTECS ..................................................................................................................... 163

3.2.6 MTECSH ................................................................................................................... 164

3.2.7 MTECI ....................................................................................................................... 165

3.3 MULTI-MASTER ...................................................................................................... 166

3.3.1 MT-…-MM ................................................................................................................. 167

3.3.2 MM TRD ................................................................................................................... 169

3.4 T-SLOT ..................................................................................................................... 171

3.4.1 SD TRD .................................................................................................................... 172

3.5 MILLTHREAD – Indexable Solution........................................................................... 174

3.5.1 MTE and MTF – Endmill and Shell Mill for Indexable Inserts ....................................... 175

3.5.2 MTFLE– Shell Mill for Indexable Inserts ...................................................................... 180

3.5.3 MTSRH – Endmill and Shell Mill for Helical Indexable Inserts .....................................................182

3.5.4 Indexable Inserts for Thread Milling ........................................................................... 184

3.6 Indexable Thread Milling Tools vs. Solid Tools ............................................................ 187

3.7 Straight vs. Helical Cutting Shape ............................................................................. 188

3.8 Thread Milling Methods ............................................................................................. 189

3.9 Entering the Workpiece ............................................................................................. 190

3.10 Climb Milling vs. Conventional Milling ........................................................................ 193

3.11 Selecting Endmill Outer Diameter for Best Effect ....................................................... 194

3.12 Depth per Pass and Number of Radial Passes .......................................................... 196

3.13 How to Choose Correct Solution? ............................................................................. 199

3.14 Cutting Conditions .................................................................................................... 223

3.15 Troubleshooting ........................................................................................................ 230

3.16 Special Request Form Thread Milling ........................................................................ 232

4 Cutting Material Grades and Engineering Materials ...................... 234

4.1 Tool Material Grades for Indexable Inserts and Solid Tools ......................................... 234

4.2 Material Groups ........................................................................................................ 236

3